Woodworkers often define the value of a machine as the speed and precision with which it processes wood. These values were taken to the next level with the advent of computer numerical control (CNC) machines in the 1970s. CNC machining service allows the woodworking process to be automated, unlike traditional machines that must be operated manually. Instead of controlling a machine during woodworking, it can be programmed to perform the desired function. With this machine, more complex woodworking can be done in less time than with conventional machines.

Cutting Precision

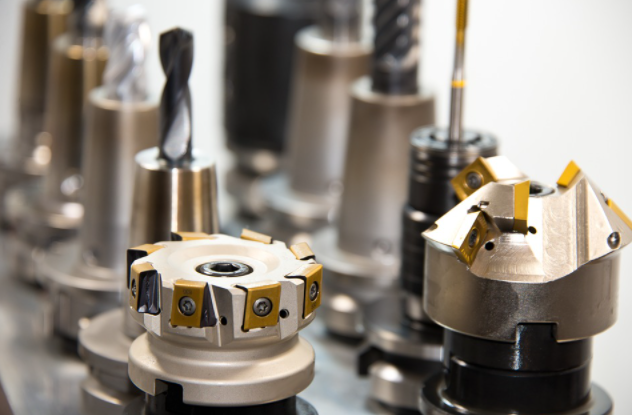

CNC woodworking machines are known for their incredible cutting accuracy. This is due to two factors: the use of multiple cutting heads and cutting according to a Cartesian coordinate system that allows for three-dimensional motion control. Thus, intricate three-dimensional designs can be created without the need for hand carving. CNC machines are attractive to both professionals and woodworkers because they can cut intricate designs. The latter benefit in other ways as well: high repeatability for large production runs.

Human error can cause scrap with manual routers. Over time, this problem can lead to lost sales and production delays due to human error. CNC machines reduce human error in the operation of woodworking machines, which is a big advantage for companies that produce a lot of wood.

Production Volume

CNC woodworking machines are valued for their exceptional cutting accuracy. Their ability to meet increasing production demands is equally impressive. Because of their computer-controlled operation, they can reduce production time and save costs. Even large parts, such as stair treads, can be produced quickly if the right size cutting table is available. Hence, these wood machines will definitely beneficial for woodworkers to support their productivity.

Many woodworkers claim that one CNC machine can do as much work in as little time as several manually controlled machines. This is true. The ability to increase the work area by replacing two or more standard machines with a CNC machine reduces labor and the number of operators.

Buying a CNC Machine

These CNC machines are expensive for industrial use. However, because of the many advantages they offer, they can be more affordable than manual machines. Many woodworkers are reluctant to buy a new CNC machine because it is too expensive. However, you can buy them second-hand from a professional dealer who sells second-hand woodworking machines. A second-hand CNC machine can often be purchased for half the price of a new machine and will continue to provide many decades of reliable service.

All in All

Professional woodworking has been greatly transformed by CNC machines. CNC machines allow you to perform complex cutting tasks that were previously impossible with industrial machines. They also allow large production runs to be scheduled without human error. Contact a salesperson for more information on the benefits of replacing a manual woodworking tool with a CNC machine.